We're one of the most professional FA One-stop suppliers in China.Our main products including servo motor, planetary gearbox, inverter and PLC, HMI.Brands including Panasonic, Mitsubishi, Yaskawa, Delta, TECO, Sanyo Denki ,Scheider, Siemens , Omron and etc.; Shipping time: Within 3-5 working days after getting the payment. Payment way: T/T, L/C, PayPal, West Union, Alipay, Wechat and so on

Our company insists all along the quality policy of “product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” and also the consistent purpose of “reputation very first, shopper first” for Low price for China Vlt Automation Drive FC 360, If possible, make sure you send your necessities with a detailed list including the style/item and quantity you require. We’ll then mail our greatest selling prices to you.

Our company insists all along the quality policy of “product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” and also the consistent purpose of “reputation very first, shopper first” for China Frequency Drive, Frequency Inverter, Now we have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we have been looking forward to even greater cooperation with overseas customers based on mutual benefits. Make sure you feel free to contact us for more details.

Spec Detail

|

Item |

Specifications |

| Gross weight | 5.0kg |

| Volume | 16.53 l |

| EAN | 5710107427338 |

| Serier | FC 360 |

| Nennleistung | 5.5 KW / 7.5 HP |

| Typecode | FC-360H5K5T4E20H2BXC |

| Typecode (Teil 2) | DXXSXXXXAXBX |

| Phase | 3 |

| Mains Voltage | 380v…480v |

| Control Card | Standard Control Card |

| Display | No Display (No Blind Cover) |

| Enclosure | IP20 / Chassis |

| RFI Filter | RFI Class A2 |

| Order Number | 134F2978 |

Match capacity to heat load – and save energy

One of the largest cost factors in the industrial refrigeration system lifecycle is energy. In many refrigeration applications, capacity exceeds heat load due to seasonal variations, product loading, occupancy variations, and electrical appliances that cause power loss. Modern, dedicated AC drives, such as Danfoss Drives’ range of VLT® drives, provide the ideal means to continually adjust the equipment capacity to the actual heat load and process needs. The benefits are significantly lower energy consumption and lower operation and maintenance costs.

Intelligent compressor and condenser/evaporator fan control are essential in any optimized refrigeration system. You can typically achieve 10–25% savings on energy consumption by applying Danfoss AC drives to optimize the capacity control of refrigeration compressors, condensers and evaporators. By creating stability while balancing the capacity to the actual load, the system-wide coefficient of performance (COP) improves providing significant energy savings.

Screw compressors controlled by an AC drive typically use 15% less energy than traditional screw compressors with slide valve control only. Optimized start/stop cycles reduce wear and tear on the compressor.

Drive-controlled reciprocating and scroll compressors have higher COP at part loads. VLT® drives are particularly suitable for controlling scroll compressors.

Cascade control optimizes energy savings and reduces lifecycle costs

Cascade configuration produces the optimal interaction between an application and an AC drive under partial loading. The base load is handled by a single application, such as a compressor, controlled by a drive. When heat load rises, the drive starts up additional compressors one at a time. This ensures the applications work at their optimum efficiency point, and the drive maintains maximum energy efficiency throughout the system.

Well-planned cascade control also ensures minimal wear on the individual applications. By rotating mains-powered compressors, for example, maintenance managers can ensure each ends up with a similar number of operating hours and an equal wear level. This increases the lifetime of the applications and extends service intervals reducing lifecycle costs.

Danfoss Drives’ advanced Multi-zone pack controller ensures effective cascading and control of up to six compressor packs. This minimizes energy consumption, avoids too frequent staging and de-staging, stabilizes pressures and temperatures, and reduces compressor wear and tear. Similarly, the Pump Cascade Controller distributes running hours evenly across all pumps to keep wear and tear on individual pumps to a minimum.

Fast commissioning

Commissioning is fast and easy utilizing the Danfoss Drives display panel that uses common refrigeration terms rather than computer language. The wizard guides the user through the necessary settings. Ease of programming makes installers and service technicians more comfortable and confident, makes their jobs easier and quicker, reduces human errors and improves employee productivity.

Our company insists all along the quality policy of “product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” and also the consistent purpose of “reputation very first, shopper first” for Low price for China Vlt Automation Drive FC 360, If possible, make sure you send your necessities with a detailed list including the style/item and quantity you require. We’ll then mail our greatest selling prices to you.

Low price for China Frequency Drive, Frequency Inverter, Now we have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we have been looking forward to even greater cooperation with overseas customers based on mutual benefits. Make sure you feel free to contact us for more details.

-

Factory Promotional China Replace Danfoss Vlt A...

-

factory low price China Sgm7j-01afc6s Yaskawa 1...

-

Hot New Products China New Useful Delta DOP-107...

-

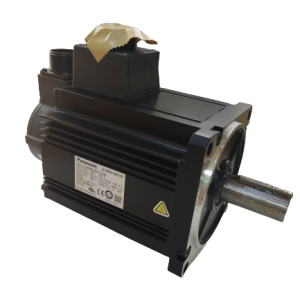

Professional China PANASONIC motor,Durable moto...

-

Hot New Products China New Useful Delta DOP-107...

-

Best-Selling China Vlt Automationdrive FC 302 (...